Phone:13616368112

E-mail:

lehualvsu777@163.com

Address: North Street East Station Shanshui Road,Zhuliu Subdistrict,Changle county.

Circular saw: Trapezoidal flat saw blades Flat saw teeth tilted at 45°, carbide Saw blade diameter: 300mm Number

If the back of aluminum-plastic panels is machined into V-grooves, it can be easily formed manually using conventional routers Cutting speed: 3000—5000 m minFeed speed: 25—30 m min

Grooving can be done with specialized cutting machines with guide plates After the V-groove processing of aluminum-plastic panels, manual operation is especially convenient

General equipment can be used for riveting and tight fixing; if used externally, the application of heat seals should be considered Blind rivets can be conveniently connected from one direction

Operating on a platform allows the bent parts to be neat Flat punch presses, folding machines or bending dies

Considering the deformation limit, our company considers e≥2D as the optimal calculation method between the hole diameter (D) and the distance from the hole center to the plate end (e)

Bending with a folding machine, minimum internal radius: r=15×t (where t refers to the thickness of the plate)

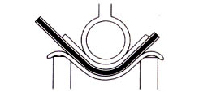

Three-roll benders are more suitable than press brakes for large inner diameter bending Pre-bending preparation should allow manual adjustment after machine bending

ACP panels drill easily For optimal results, use drilling machines designed for aluminum and plastic For large